Experience the Future of Delivery with Our Smart Parcel Lockers Welcome to Parcel Hive

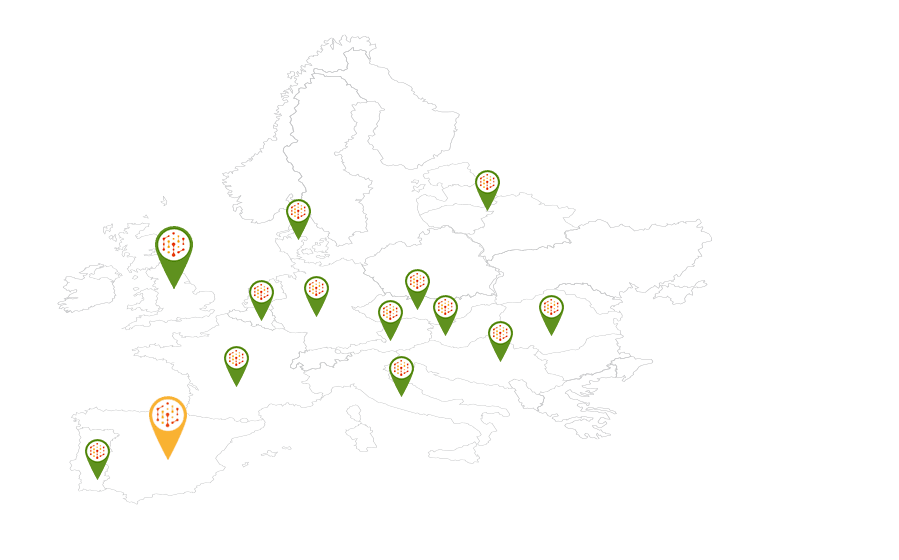

Global Coverage

Global Coverage

Cyber Hive – The Ultimate Software Solution

Our Cyber Hive software sets the industry standard, providing an intuitive, seamless experience for every user. Enjoy advanced reporting and support features, along with automated remote management, eliminating the need for on-site personnel.

Custom-Tailored Solutions

We understand that every customer is unique. That’s why Parcel Hive offers custom-sized lockers and bespoke services designed to meet your specific needs. Experience delivery solutions crafted just for you.

Products

Parcel Hive Parcel Locker Features

Meet us at Parcel+Post Expo 2024 in Amsterdam!

Meet us at Parcel+Post Expo 2024 in Amsterdam!

Time

20.10.2024

Location

Amsterdam

Netherlands

Parcel Hive at SIL Barcelona 2024

Parcel Hive at SIL Barcelona 2024

SIL Barcelona reaffirmed its position as a pivotal event for logistics and transport in Southern Europe.

Time

5-7.06.2024

Location

Barcelona

Spain

Meet us at LogiMAT 2024

Meet us at LogiMAT 2024

LogiMAT 2024 – Stuttgart, Germany (March 19-21)

LogiMAT 2024 in Stuttgart was a stellar start to our event calendar.

Time

Location

Leave your comment

Case Study: Imperial Hotel London – Luggage Storage Locker Service

Imperial Hotel London offers convenient luggage storage lockers, allowing guests to explore the city freely between checkout and their departure.

Case Study: Kapes School Uniforms – Revolutionizing Uniform Management with Smart Click & Collect Parcel Lockers

Kapes UAE transforms school uniform management with Parcel Hive's Click & Collect lockers, offering sustainability, safety, and a seamless student experience.

Our Headquarters and Manufacturing Facility

148, Kliment Ohridski Blvd. Sofia 1756, Bulgaria

C/Colegiata N18, 28012, Madrid, España

Phone Numbers

+ 359 2 408 58 88

+ 34 (91) 0607378

Email Addresses